Beyond the Blueprint: Why Revit As-Builts Are Transforming Existing-Conditions Documentation

At FSU, every Revit As-Built begins with high-precision scanning, delivering accuracy within ¼” of real conditions.

When it comes to documenting existing conditions, accuracy isn’t just helpful, it’s mission-critical. In an industry where outdated floor plans and incomplete information can lead to costly redesigns and construction delays, Revit As-Builts are emerging as the new standard. At Field Services Unlimited (FSU), our nationwide survey network and advanced laser-scan technology give designers, architects, and engineers the real-world clarity they need before a single line of design work begins.

Below, BIM & Administration Manager James Corrao breaks down what makes Revit As-Builts so powerful, how they drive the broader BIM workflow, and why more brands—especially multi-site operators—are making them their go-to foundation for confident decision-making.

What Makes a Revit As-Built Different

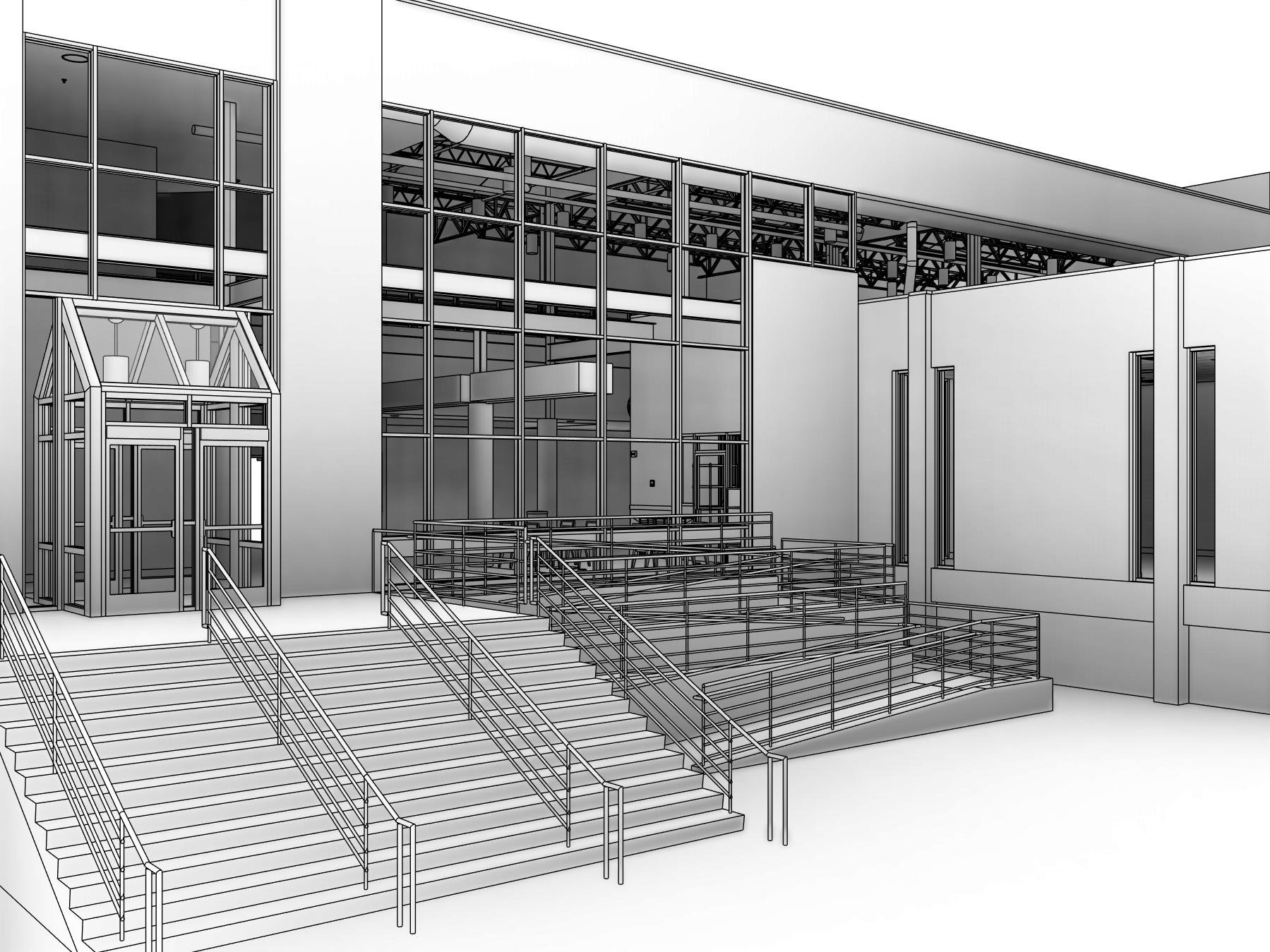

A Revit As-Built is far more than a 2D drawing—it’s a highly accurate, data-rich 3D model built directly from laser-scan field capture. Unlike traditional CAD drawings, where geometry is drafted manually, Revit uses parametric components (“families”) that can store detailed metadata for walls, equipment, ceilings, mechanical systems, structure, and more.

At FSU, every Revit As-Built begins with high-precision scanning—Leica RTC360, BLK2GO, Matterport, 360° imagery—delivering accuracy within ¼” of real conditions.

This level of precision gives design teams:

Exact geometry and dimensions

A visual, data-driven representation of existing conditions

Customizable families embedded with manufacturer or equipment details

Intelligent relationships between components, reducing guesswork during design

Revit also excels at coordination and automation: integrated point clouds prevent clashes early, schedules generate instant equipment lists and takeoffs, and designers gain a reliable, verified baseline before any planning begins.

Revit As-Builts Power Better Design, Planning & Cost Control

A Revit As-Built is the starting line of the entire BIM workflow. Before architects draft, before engineers route systems, and long before contractors mobilize, the model provides a unified, accurate view of the existing space.

Teams rely on these models to:

Reduce site visits with a complete digital replica of the space

Validate ceiling heights, clearances, mechanical pathways, and structural constraints

Produce clean plans, elevations, RCPs, and MEP diagrams

Generate true square footage and precise quantities for better cost estimating

Catch conflicts—sometimes decades of undocumented changes—before they affect construction

FSU’s models also directly support our Site Survey Reports and Due Diligence Reports, giving clients documentation that ties back to scan data, not hand-written notes. This makes every deliverable more accurate, more visual, and more defensible.

Real-world impact:

In one national retail project, the design team relied on drawings from the 1990s—only to learn through our scan-based Revit As-Built that multiple walls had moved and utilities had shifted into planned entrance pathways. The accurate model prevented major rework, avoiding expensive field changes and keeping the project timeline intact.

For multi-site programs, retail rollouts, and adaptive reuse projects, this level of consistency is game-changing. Whether the location is in New York, Texas, or California, FSU delivers the same standardized model, naming conventions, and Level of Development (LOD) — at scale. The LOD describes how detailed, accurate, and reliable each element in the model is at different project stages. The LOD may be as simple as a cube showing basic space and volume or as detailed as components that include materials, appearance, dimensions, and embedded data.

FSU Ensures Accuracy, Quality, and Uniformity Nationwide

Behind every Revit As-Built is a disciplined process designed to remove guesswork and deliver uniform quality across every market. FSU’s approach blends advanced technology, documented workflows, and a nationwide survey network trained on the same high standards.

Here’s what that looks like in practice:

· Structured and repeatable field capture

Every project begins with a clear scope and an on-site workflow using Leica scanners, Matterport, 360° photos, and high-resolution stills. Whether it’s a single location or a 300-site rollout, capture methods remain consistent.

· Client-aligned modeling standards

FSU works within client-specific templates—naming conventions, LOD expectations, family libraries—to ensure every model integrates seamlessly into their broader design or BIM ecosystem.

· A rigorous multi-step QC process

Every model undergoes detailed internal quality checks, so it never looks like one person’s work. The result: consistent geometry, uniform annotation, and deliverables that meet the same standard no matter who created them.

· Nationwide repeatability

Because FSU trains surveyors and drafters on the same methodology, clients get reliable, predictable output from Los Angeles to Long Island. For brands scaling rapidly or renovating multiple locations, this reduces risk, speeds up planning, and creates a unified dataset across all sites.

Revit As-Builts are redefining how existing conditions are documented, giving architects, engineers, and project teams a richly detailed, highly accurate foundation for every phase of planning and design. By combining laser-scan precision with intelligent, data-driven modeling, FSU delivers As-Builts that eliminate guesswork, reduce site visits, prevent costly surprises, and ensure consistency across single sites and large national programs. With a disciplined capture workflow, client-aligned standards, and a rigorous QC process, FSU provides the reliable, uniform documentation that modern projects demand—no matter the location, scale, or complexity.